Learn About The Reasons To Do Galvanised Steel As Compulsory Note

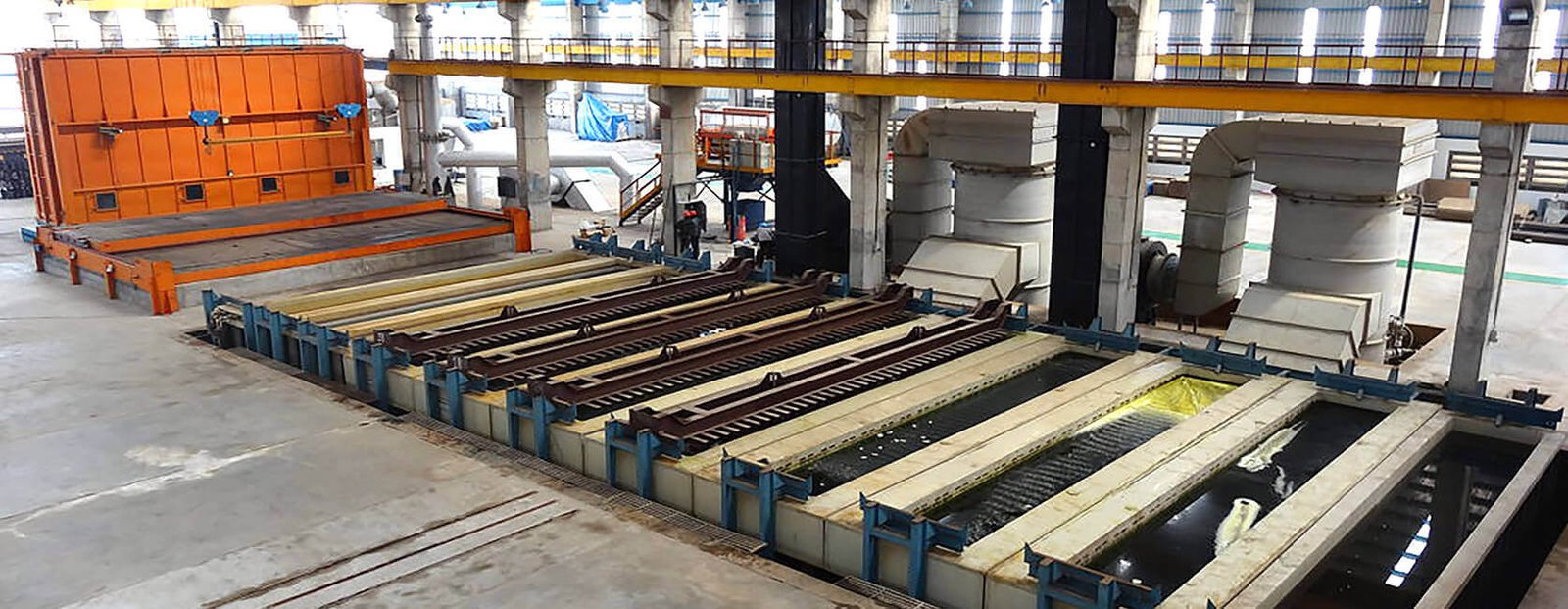

Hot plunge galvanizing steel is surrounding us and assumes a significant part of our constructed climate. Hot Dip Galvanizing Plant In Ahmedabad is the interaction by which clean steel is inundated into liquid zinc to acquire a covering that is metallurgically attached to it. The interaction gives long haul consumption security, just as numerous extra advantages that may some of the time be neglected, failed to remember, or misconstrued.

What is aroused steel utilized for?

With a set of experiences that stretches back more than 150 years, there are countless instances of excited steel being used in numerous conditions, which demonstrate its presentation.

Galvanizing steel is surrounding us, in an entire assortment of enterprises including street, rail, energy plants, oil and gas, agribusiness, water and waste, and sports and relaxation. It can assume a significant part for structures, spans, exteriors, signal gantries, doors, overhangs, and even models. Any place there is a danger for the consumption of steel, arousing ought to be utilized.

What Are The Benefits Of Galvanizing Steel?

Hot Dip Galvanizing Plant offers numerous preferences and advantages: it's demonstrated, legit, supportable and the sky is the limit from there. Discover underneath why it is essential to galvanize steel.

-

Galvanizing is Durable

A Hot Dip Galvanizing Process is quite possibly the strongest type of consumption assurance available. A normal covering thickness of 85 microns, a similar thickness as a sheet of A4 paper, can secure a steel structure for the majority of 100 years.

One of the inalienable advantages of hot plunge stirring is that when clean steel that is more prominent than 6mm thick is lowered into liquid zinc, it will build up a base mean covering of 85 microns.

-

Galvanizing is Sustainable

A few investigations have shown the high financial and natural expenses related to the rehashed support painting of steel structures. These weights can be essentially decreased by an underlying interest in long-haul insurance.

-

Galvanizing is Cost-successful

The genuine expense of shielding steelwork from consumption needs to think about two significant components, the underlying expense of security and the lifetime cost. Galvanizing Plant is frequently seen to be more costly than it is. There are two purposes behind this: Firstly, that a particularly superior covering is consequently thought to be costly. Besides, the underlying expense of exciting comparison with paint has changed altogether over years. Painting costs have consistently expanded while arousing costs have stayed stable.

Source: https://arvindcorrotechindia.wordpress.com/2021/05/19/why-steel-require-hot-dip-galvanizing-process-know-with-experts/

.webp)

.png)

.webp)

Comments

Post a Comment