Hot Dip Galvanizing Plant is a ground-breaking innovation

Mankind’s zeal to overcome looming challenges has been instrumental in giving birth to many discoveries and inventions. The Hot Dip Galvanizing Plant is a classic example demonstrating mankind’s persistent determination to brighten the future.

What’s Hot Dip Galvanizing Plant

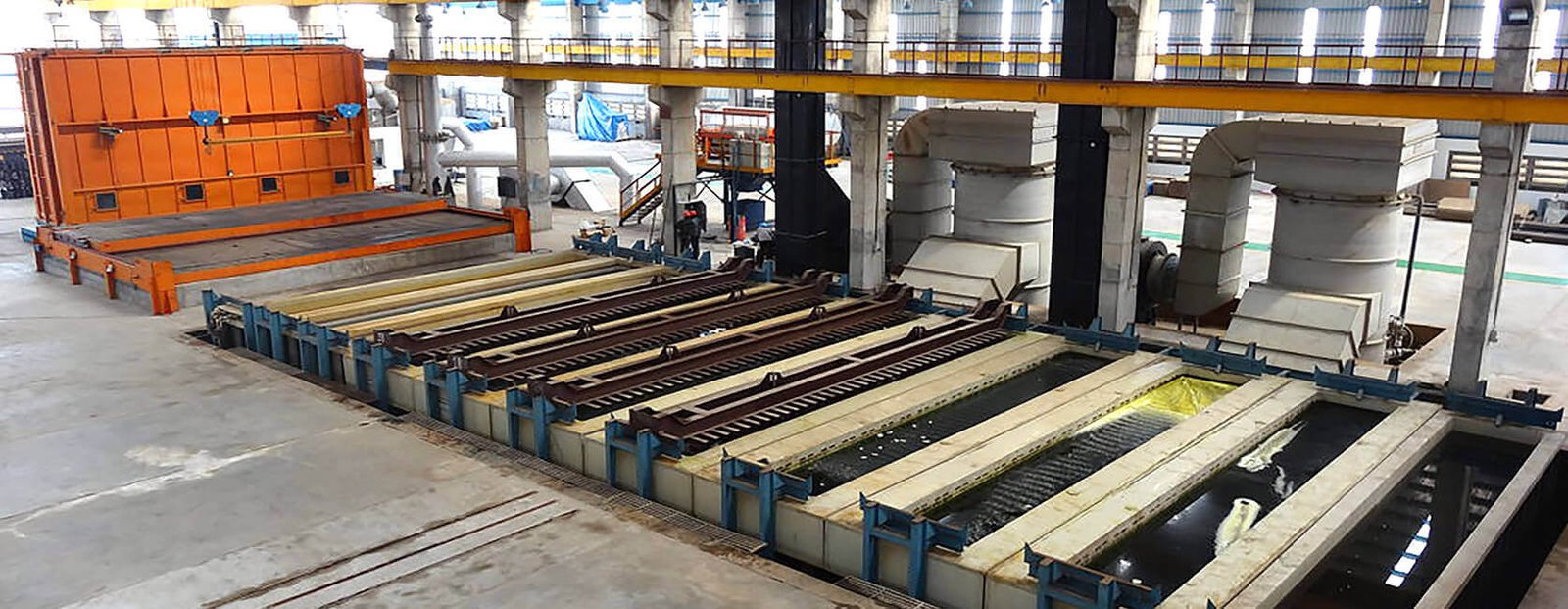

At the outset, it assumes significance to comprehend the new age innovation, often described as the ground-breaking innovation for mankind. The Hot Dip Galvanizing is a sophisticated process wherein a coating of zinc is developed on metallic and steel products when immersed in a bath of molten zinc. The zinc coating protects the metallic material from corrosion and inclement weather conditions.

Application

This blog has been appropriately called as ground-breaking innovation, it isn’t an exaggeration. Here are a few applications reflecting the significance of Hot Dip Galvanizing Plant and Small Hot Dip Galvanizing Plant:

Power Transmission Line Tower

The power transmission line tower is a gigantic metallic structure that is leveraged to transmit power from point of generation to far-flung areas. These metallic structures are continuously exposed to inclement weather, rainfall, and cyclone among others. Corrosion impacts their durability. Galvanization protects the structure from corrosion and increases durability.

Bridges

Metallic rods and steels are used to develop the basic structure of bridges. However, exposure to harsh weather conditions corrodes the metallic material. In such scenarios, the Hot Dip Galvanizing Companies assumes significance. The use of Galvanized metal in bridge construction increases the lifespan of the bridge.

Automobile industry

Automobile industry can’t imagine their existence without galvanization. Automobiles, including two wheelers and four wheelers rely heavily on hot dip galvanization plants. A wide range of tools, spare parts, nuts and bolts which are being used in the manufacturing are first galvanized. Galvanization shields the material from corrosion. Owing to this salient features, automobiles withstand harsh weather conditions. Proud owners don’t have to worry about the corrosion and its impact on their proud possession.

Galvanization is expensive

Calling galvanization expensive is a misconception. Perhaps, a lobby that opposes the impact of galvanization lives in their own self created world. They are cut-off from the reality; fabricate excuses to oppose the revolutionary development. Research on galvanization has proved all the detractors wrong. Calling it expensive isn’t astute. In fact, it’s akin to opposing the innovation. Industry experts and research have shown that considering the impact of the ground-breaking innovation, it’s affordable and reliable. Companies cutting across domains are leveraging the process.

.webp)

.png)

.webp)

Comments

Post a Comment